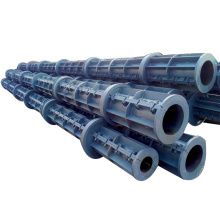

Street Light Shell Die Casting Mould Making

| Payment Type: | L/C,T/T |

|---|---|

| Terms of Trade: | FOB,CFR,CIF,FCA |

| Min. Order: | 1000 Set/Sets |

| Delivery Time: | 70 Days |

| Packaging: | Wooden box |

|---|---|

| Productivity: | 500000shots/mold life |

| Brand: | Ceeto |

| Transportation: | Ocean,Air |

| Place of Origin: | China |

| Supply Ability: | 5000sets/month |

| Certificate: | CE |

| HS Code: | 8480411000 |

| Port: | Ningbo,Shanghai |

Basic Info

Model No.: CT-10212

Click on the follow link to find out more information: https://www.ceetomold.com/led-street-lamp-lighting-enclosure/

Company Info

- Company Name: Zhejiang Ceeto Mold Co.,Ltd.

- Representative: WANG JUAN

- Product/Service: Plastic Injection Molds for Automotive , Plastic Injection Molds for Washing machines , Plastic Molds for air condition , Medical Consumer Goods Plastic Injection Mould , Die Casting Moulds and Products , Plastic Molds for Daily commodities

- Capital (Million US $): 10,000,000RMB

- Year Established: 2018

- Total Annual Sales Volume (Million US $): US$1 Million - US$2.5 Million

- Export Percentage: 71% - 80%

- Total Annual Purchase Volume (Million US $): Below US$1 Million

- No. of Production Lines: 2

- No. of R&D Staff: 11 -20 People

- No. of QC Staff: 5 -10 People

- OEM Services Provided: YES

- Factory Size (Sq.meters): 10,000-30,000 square meters

- Factory Location: No.78 Baiyunshan Road, Ningbo,China

- Contact Person: Ms. Jenny Wang

- Tel: 86-574-86863623

Premium Related Products

Other Products

Hot Products

EM-F-A079 Brass flange type double ferrule compression fittingEM-V-B208 Brass Manual 2-Way Double Heating Regulating Radiator ValveEM-V-B060 Yellow plastic hat Professional brass safety valve for air compressor pressure relief valveEM-V-B064 Brass antirust Pendent Fire Fighting Sprinkler Head NozzleEM-F-B024 Nickel plated thread Brass Union Russia Pipe fittingEM-F-B068 Spain 90 degree Pex Fitting with brass Drop Ear Elbow pipeEM-F-B040 Heating radiator valve for manifoldEM-F-B044 1/2" Nickel brass manifold ball valveEM-F-B046 Brass 4 way manifold with Threaded outletsEM-F-B048 Thread 3/4" brass manifold pipeEM-F-B146 Male thread connector equal diameter pass pex al pex jointEM-F-B156 Brass union for PVC pipeEM-F-B182 NPT male thread compression brass adaptor pipe fittingEM-F-B189 Male thread brass plug pipe fittingEM-F-B208 Thread brass reducing union pex pipe fittingEM-F-B217 Customized full size copper pipe fitting